By

Youth unemployment is a global issue. According to a McKinsey & Company report, young people worldwide are three times more likely than their parents to be out of work. In the Organization for Economic Co-operation and Development (OECD) countries, more than one in eight of 15 to 24-year-olds are NEET (Not in Employment, Education or Training). The International Labor Organization estimates globally, 75 million young people are unemployed. Yet many entry-level jobs around the world remain unfulfilled because companies cannot find employees with the right skills.

Add to this crisis the misleading narrative that to secure a good, long-term job, you need a four-year college degree. Sure, a college degree is an asset in the United States and abroad, but there are other ways to secure a sustainable career, especially in manufacturing.

Minding The Skills Gap In Manufacturing Through Paid Internships

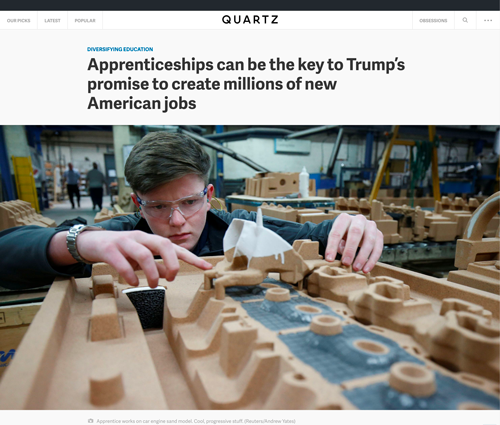

As the manufacturing sector shifts towards more highly skilled jobs, Arconic Foundation and Legacy Alcoa Foundation are working on innovative solutions to provide the training and experience necessary for young employees to fill these positions through its Global Internship Program for Unemployed Youth.

Since the program’s inception, more than 700 unemployed youth (aged 18 to 24) in Australia, Brazil, Canada, France, Russia, Spain, the United Kingdom and the US received workforce readiness training and paid internships with local manufacturers. An often-overlooked source for building the advanced manufacturing talent pipeline, unemployed and underemployed youth are critical to our local industry’s future success.

Under the watchful eye of their employers, interns are learning skills on the job to serve them for decades to come. A mid-program evaluation of the program revealed some startling discoveries:

• before their internship, interns often struggled to build confidence; 90% of participants said they gained confidence in their abilities because of the program;

• their experience allowed them to learn skills to feel better able to contribute;

• among the top takeaways from their intern supervisors was the importance of time management, which interns honed during their workplace experience.

Recognizing The Power Of Soft Skills

While new and emerging technologies are redefining the nature of today’s workforce, relationships are important. That’s particularly true for industries not usually associated with offering soft skills or opportunities such as genuine mentorship.

For example, intern Elizabeth Kaehr said mentors were an integral part of her internship experience – she had several while at work at the City of Lynden’s waste and water treatment plant. She secured her internship while a student at Bellingham Technical College in Washington. Kaehr learned how to collect water samples, collect compost, do pressure washing as well as how to clean out pump stations and sedimentation basins and retrieve and test samples. She says her mentors helped guide her on hard career decisions and appreciate opportunities new to her. The relationships she developed through her internship, she says, will help her advance her career.

Similarly, oceans away, Caitlyn participated in a six-week paid internship at Accredited Distributors, an industry partner of Northern Futures, which works with Legacy Alcoa Foundation. Living in supportive youth housing, Caitlyn was able to access resources and training through the partnership. It meant she was job-ready to apply for warehouse roles after the program. What got her there was learning a range of tasks and receiving one-on-one attention to do so. She developed confidence and skills in picking and packing with a scanner and also driving a forklift and unloading a truck.

When she graduated, she learned she was selected to take part in a year-long full time employment project, 180 Degrees at Cotton On Group Distribution Centre, an Australian clothing retailer with almost 1,200 stores in 12 countries, and 17,000 employees worldwide. Caitlyn tapped into skills she developed while an intern during the 2014 project.

Employers Benefitting Through Partnerships

In many cases, it’s not just the mentees and interns who benefit. Manufacturers gain motivated interns eager to learn and show their worth to prospective employers. That helps them increase their bottom line. Also, manufacturers can learn new ways to tackle issues they may not have considered.

Youth unemployment might be a global issue. But it can be solved with innovative programs and partners who are willing to work together to provide the necessary soft and hard skills to our youth.

Investment in our youth goes beyond feeling good about being a good corporate citizen, although an argument could be made that it’s an important consideration.

Investments in manufacturing have contributed to better standards of living and more jobs and they’re having a ripple effect for the broader economy. According to The Manufacturing Institute’s Skills Gap Report, every dollar spent in manufacturing adds $1.37 to the U.S. economy and every 100 jobs in a manufacturing facility creates an additional 250 jobs in other sectors.

Manufacturing and supporting our youth matters.