By Nicholas Wyman.

In my previous post I talked about the “buy or build” choice for closing the skills gap. Do you compete in a tight labor market (buy); or train new workers yourself (build)?

In this post I review the costs and benefits of the latter option—building a skilled workforce with an apprenticeship program.

First, let’s review some of the benefits of apprenticeship:

- apprenticeship develops highly skilled employees suited to the unique requirements of your workplace;

- apprenticeship leads to innovation at the host firm;

- apprenticeship lowers long-term recruitment and training costs;

- only a small percentage of apprentices go elsewhere after they complete training.

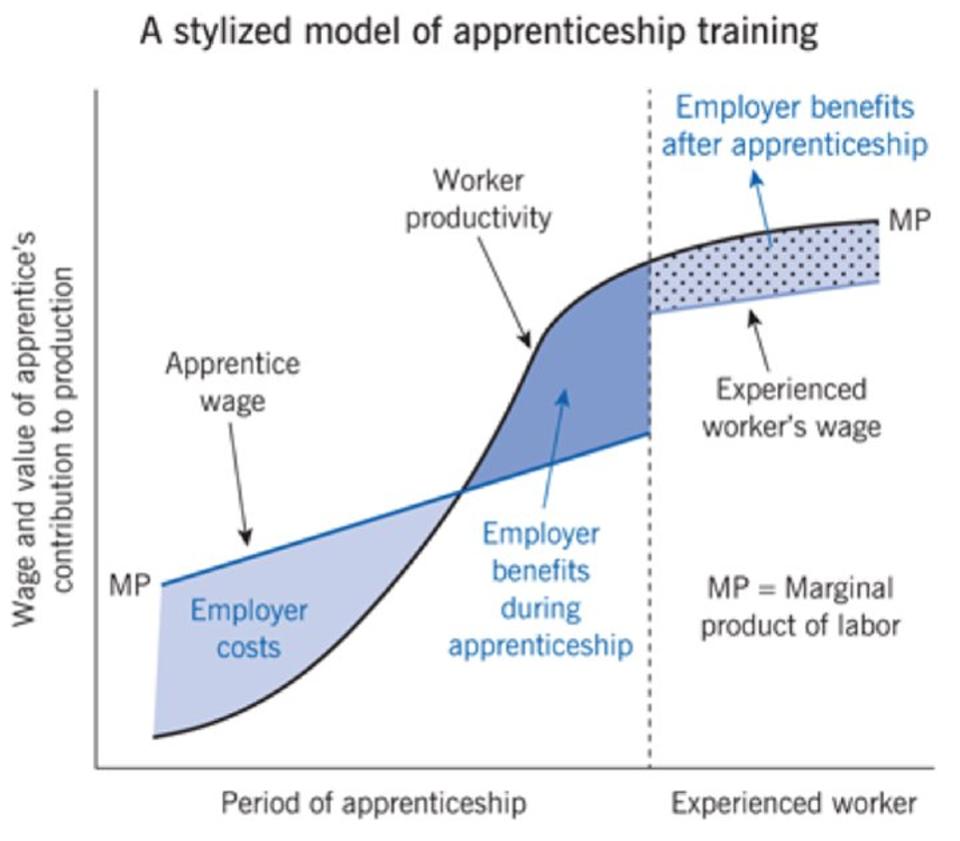

But how can you measure these kinds of benefits? Good question. Costs are a bit more straightforward. Employers can easily estimate the cost of apprentice wages and fringe benefits over several years, as well as the cost of classroom training. You can also get a reliable cost estimate for the time mentors (or job coaches) spend with apprentices. Measuring benefits is more challenging, owing to the difficulty of measuring apprentice productivity over several years.

Nevertheless, independent researchers as well as individual companies have attempted to do so. In one study, European economists found the productivity of Swiss apprentices compared to skilled workers increased from 37% in the first year of training to 75% by the end of a three-year program. Their German counterparts advanced in productivity at roughly the same pace. Additionally, 60% of the Swiss firms recouped their costs during the training period, while the German firms, on average, required more time to break even (German apprentices spend more time than their Swiss counterparts in the classroom and practicing tasks.) But the point is that costs are recouped, and more quickly than many employers might realize.

Larger, more ambitious cost-benefit studies have been undertaken in Australia, Canada and the U.K. To summarize the key findings:

Figure 1

Source: Modified Figure Based On Gambin, L., C. Hasluck, and T. Hogarth. “Recouping the costs of Apprenticeship Training: Employer Case Study evidence from England.” Empirical Research in Vocational Education Training 2:2 (2010); 127-146.

· Costs and benefits of apprentice training vary between nations, industries, and occupations. For example, in Canada, it costs roughly 3 ½ times more to train an electrician than to train a cook, which means it takes longer for employers training electricians to break even.

· Sponsoring companies either reach break-even within the training period itself or shortly thereafter. But they do break even and go on to positive gains. (See Figure 1).

The American experience

In contrast to Europe and Australia, U.S. firms are latecomers to apprenticeship. Nevertheless, an overwhelming majority of 900 employers surveyed said their programs produced net economic gains. Almost all reported that apprenticeship helps them meet their skill requirements and 87% said that they would strongly recommend registered apprenticeship to others. Only one in four regarded “poaching” of apprentice graduates as a serious concern. And even 85% of these would highly recommend apprenticeship to others.

Surveys and academic studies aside, common sense tells us that firms with decades of experience in apprenticeship—such as Siemens, Volkswagen and Newport News Industrial—would have abandoned apprentice training if it failed to produce net positive results. But they haven’t. On the contrary, these companies tout their apprentice systems. And when they set up operations in North America, one of the first things they do is create apprenticeship programs customized to their skill needs and local conditions, often in collaboration with local high schools and two-year colleges. They know from experience that program graduates will be skilled, productive and fully versed in workplace processes and protocols—“the way things get done around here”—in a way outside hires simply can’t be.

Employers with strong apprenticeship programs also benefit from reduced employee turnover and onboarding costs. Managers and supervisors have several years to observe their apprentices on-the-job and gauge their interpersonal skills before offering them official positions. And so their hiring decisions will be better than those who rely only on resumes and interviews and hope for the best.

Your choice

So, if your company is short on skills, should you buy or build?

If you buy, you may be casting a line into a shallow pond that’s been mostly fished out. But if you build—by developing talent through a modern apprenticeship program—you’ll find yourself with a highly skilled and motivated workforce in just a few years. It may require more time and money upfront, but building can be the better strategy.